LMV Linkageless Burner Management System

World-class system, support, and performance

Resources

World-Class System, Support, and Performance

The LMV3 Linkageless Burner Management System sets a new standard for cost effective single or dual fuel burner controls – from easy installation, programming and commissioning to reliable, proven control. Effortless commissioning, simple programming, and easy installation allows for maximum ROI. With the LMV3, Siemens forges new ground delivering a fully integrated flame safeguard, linkageless system that is not only easy to install and use, but also provides improved burner performance and efficiency and ensures safe operation. Key features and benefits:

- Single and dual fuel versions

- Effortless commissioning, simple programming, and easy installation allows for maximum ROI.

- Programming via a keypad or PC

- Independent actuator positions for home, pre-purge, ignition, and post-purge

- Proof of Closure switch monitoring

- LMV3 will accept a 4-20mA firing rate control signal from any PID controller

- And many more!

Experience Linkageless Burner Management Systems

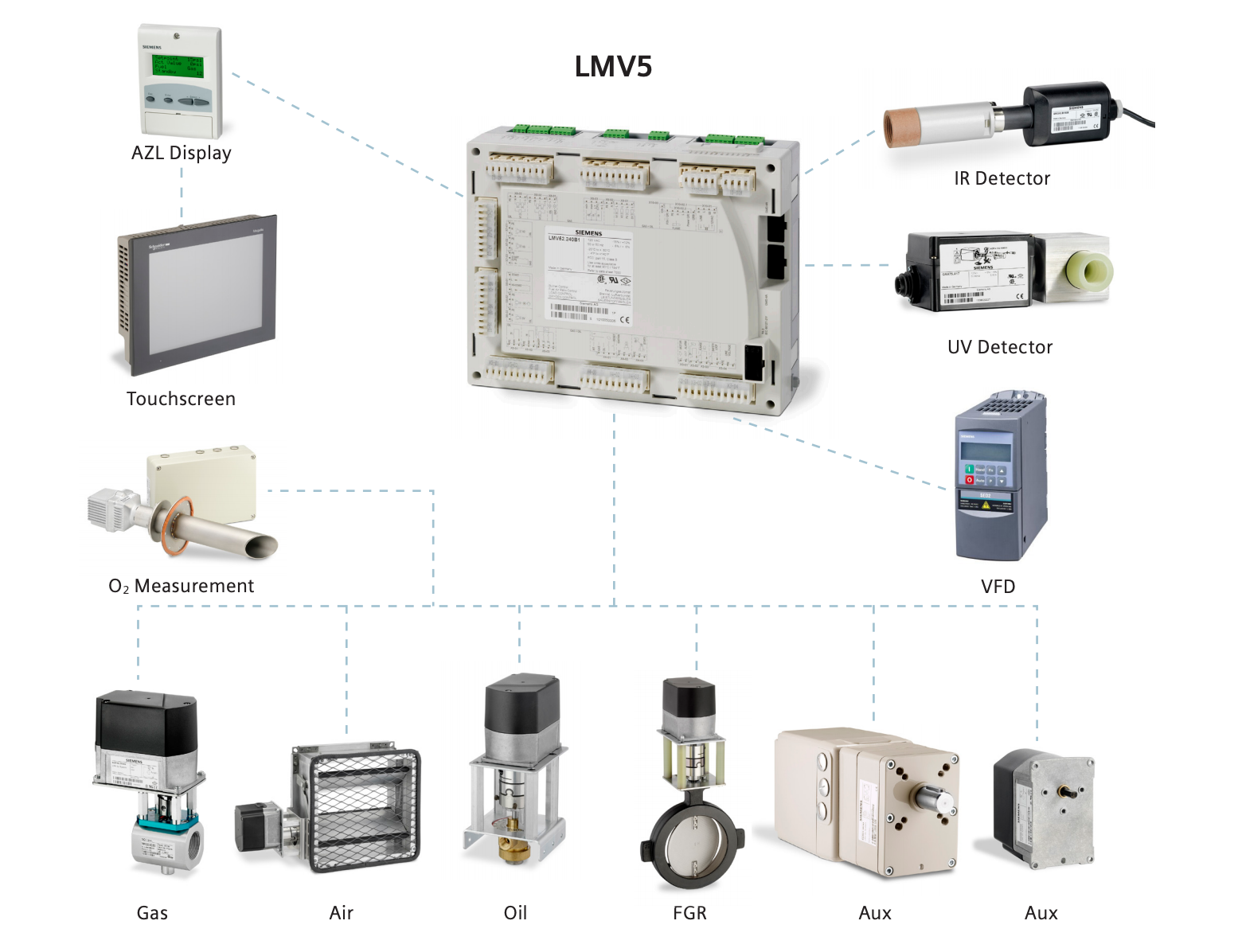

The LMV5 Linkageless Burner Management System sets the standard high - from easy installation, programming and commissioning to reliable, proven control. With the LMV5, Siemens forges new ground delivering a fully integrated system that is not only easy to install and use, but also provides improved burner performance and efficiency and ensures safe operation.

- Fuel to air ratio curve can easily be adjusted at any point in the firing rate

- 15 programmable points, with 4 independent positions including pre-purge, ignition, post-purge and standby

- User friendly menu system for fast programming and commissioning

- Worldwide approvals and technical support

LMV ECOSYSTEM

Fully Integrated, Easy-to-Use HMI

Accuracy is the Key to Control

Programming and commissioning of the LMV5 takes minutes, not days. Simply log in, select the programming option and define the specific parameters. It is that easy!

- User-friendly, menu system for fast programming and commissioning

- Quickly access and monitor the system at all times

- Real text annunciation of fault conditions for fast troubleshooting

- Multi-level password protection for added security

- Real-time ModBus communication

Driven by a digital Can-Bus signal, the movement of the SQM4 actuator is accurate to 1/10th of one degree. A digital feedback signal ensures the correct position is maintained throughout the modulating range.

Accurate control ensures that the burner will always perform with repeatability and accuracy as well as within the recommended safety parameters.

Additional Options for Saving Energy

Fuel Air Ratio Control & Flame Monitoring

Communication & Annunciation

.png)

The Siemens LMV3 is capable of positioning up to 2 actuators and one Variable Speed Drive (VSD) simultaneously on programmed curves with an accuracy of 0.2 degree (actuators) and 0.1% (VSD). Standard programs offer many fuel train options, including staged oil and PWM control.

- Separate, programmable actuator positions for ignition and low -fire

- Nine programmable points per curve, per fuel

Reliable Flame Monitoring:

- Optional UV or Flame Rod supervision

- No exchange of amplifiers or controls necessary

- Simple configuration selects appropriate flame detector

.png)

The LMV system has a variety of communications and annunciations which include:

- RS485 Modbus RTU Communications

- Access to more than 40 read/write registers enable precise burner supervision and control

- Registers include:

- Fault History

- Lockout History

- Flame Signal Intensity

- remote firing rate control

- Fuel Flow (via flow meters connected to LMV3)

ACS410 PC Commissioning Tool

- Windows-based

- Optional Commissioning tool

- Ability to configure, back-up and restore information to a PC

- View real time data

- Trend, log, and print data

Different Burner Management Systems

LMV51

LThe LMV51 includes integrated linkageless control, burner flame safeguard, and modulating PID control. The LMV51 controls up to 3 actuators simultaneously, with 900 highly repeatable actuator positions for precise control. Unmatched performance, worldwide approvals and technical support make the LMV51 a leader in the linkageless control market.

LMV52

Incorporating all of the features of the LMV51, the LMV52 offers high impact options including O2 Trim, Variable Frequency Drive control, and additional actuator control possibilities. The LMV52 provides the ultimate flexibility to safely meet control needs, improve process control and reduce energy costs.