.png)

XNX™ Transmitter

Universal transmitter for toxic, oxygen and combustible gas detection

Resources

XNX Universal Transmitter

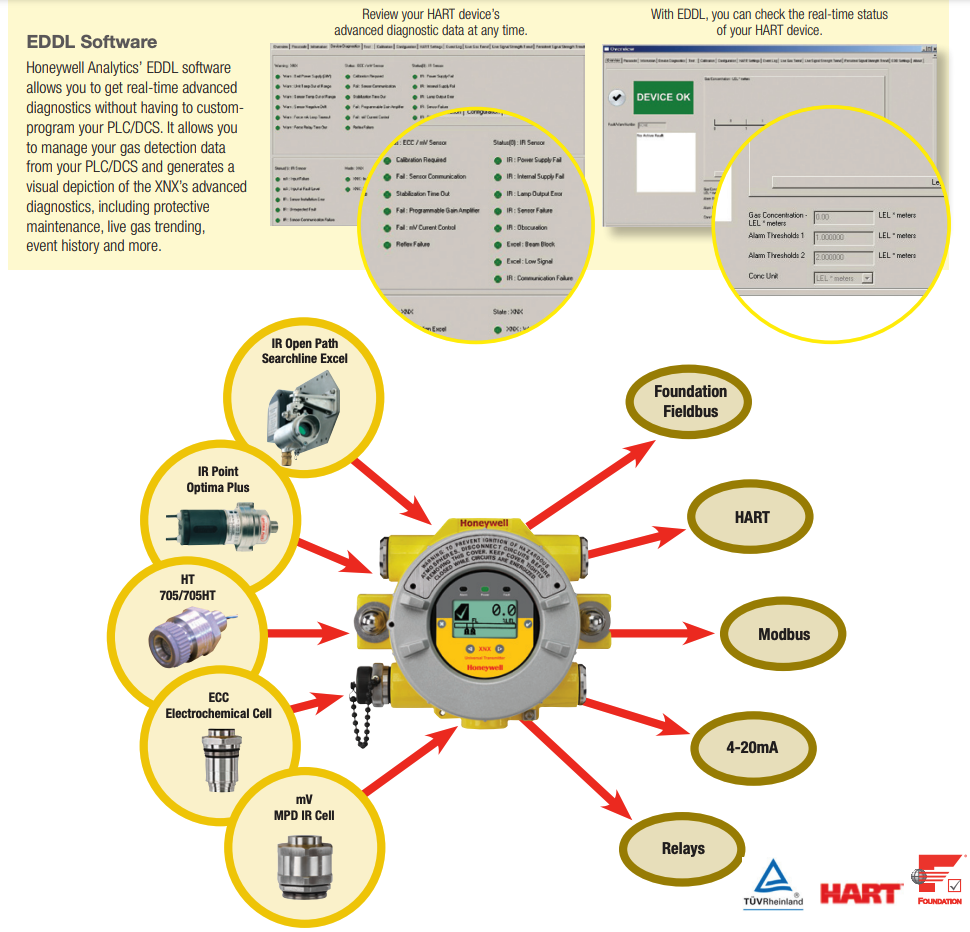

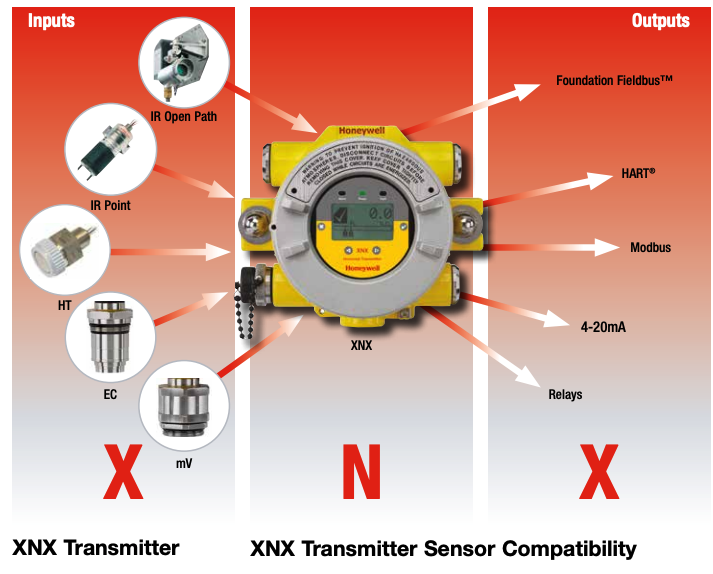

XNX is an extremely flexible transmitter that can be configured to accept an input from any of the Honeywell Analytics range of gas sensor technologies. It can also be configured to provide a wide variety of industry standard output signals. This enables users to have a single type of interface to all their gas detection needs, even when different types of detectors are employed, to most effectively address the different gas detection applications on site.

The most effective gas detection systems often employ a variety of detection technologies including point flammable detectors (both catalytic and infrared type), toxic and Oxygen electrochemical cell type detectors and open path infrared detectors. XNX provides a common transmitter interface to all of these and can be configured to provide industry standard signal outputs to match the individual requirement of each application or the preferred site standard. If site output standards change, XNX can be reconfigured to provide the new required output. XNX has also been futureproofed by having the ability to have other output modules fitted as new output standards are developed and adopted by industry.

Applications & Lines of Business:

Commercial

Gas detection from standalone units to fully engineered, multi-point systems, all offering cost-effective regulatory compliance

- Applications: parking structures, chillers, mechanical rooms, office towers, commercial buildings, shopping centers, swimming pools, golf courses, schools, and universities, laboratories.

Industrial

Renowned Sieger and Manning gas detection systems with advanced electrochemical, infrared and open path sensing technologies

- Applications: oil and gas, cold storage, water/wastewater treatment, chemicals, engine rooms, plastics and fibers, agriculture, printing and light industrial

Portables

Single or multi-gas and other premium detectors with compact, lightweight designs ranging from simple alarm only units to advanced configurable instruments.

- Applications: underground utility and electricity ducts, boiler rooms, post-fire sites, sewers, industrial plants, industrial hygiene, first responder teams, remote fleets

Universal Gas Sensing and Communications Platform

XNX Universal Transmitter - Inputs & Outputs

LXNX has Worldwide hazardous area and

performance approvals and is housed in

a flameproof enclosure that is available in

either painted marine grade aluminum alloy

or stainless steel 316 versions. A large backlit

multilingual LCD clearly indicates the unit’s

status using a combination of text, digits and

icons. Users can modify its operation using

the LCD and magnet switches without ever

needing to open the unit. An optional local

IS HART® terminal port is also available.

Both enable one man, non-intrusive, operation

and reduce routine maintenance time and

costs. Local LEDs are also provided to indicate

the unit’s status at a glance.

XNX is compatible with all of the Honeywell Analytics range of industrial fixed gas sensors including Searchline Excel, Searchpoint Optima Plus, Sensepoint (HT and PPM) and Model 705. For further information on these sensors, please refer to their individual datasheets.

LThe Multi Purpose Detector (MPD) is a serviceable stainless steel sensor housing with plug-in catalytic and infrared sensor cartridges. The catalytic sensors measure flammable gases in the range 0-100%LEL and the infrared sensors measure Hydrocarbons in the range 0-100%LEL, or Methane 0-100%LEL (or 0-5%Vol) and CO2 0-5%Vol.

See the specifications section for full details of the MPD sensor. The XNX EC sensor is also a serviceable stainless steel sensor with a wide range of toxic and Oxygen plug-in sensor cartridges. The XNX EC sensor interface to the XNX transmitter is intrinsically safe, allowing the sensors to be ‘hot swapped’ without the need for a hot work permit. This reduces the cost of ownership by reducing the cost and time to service the detector.